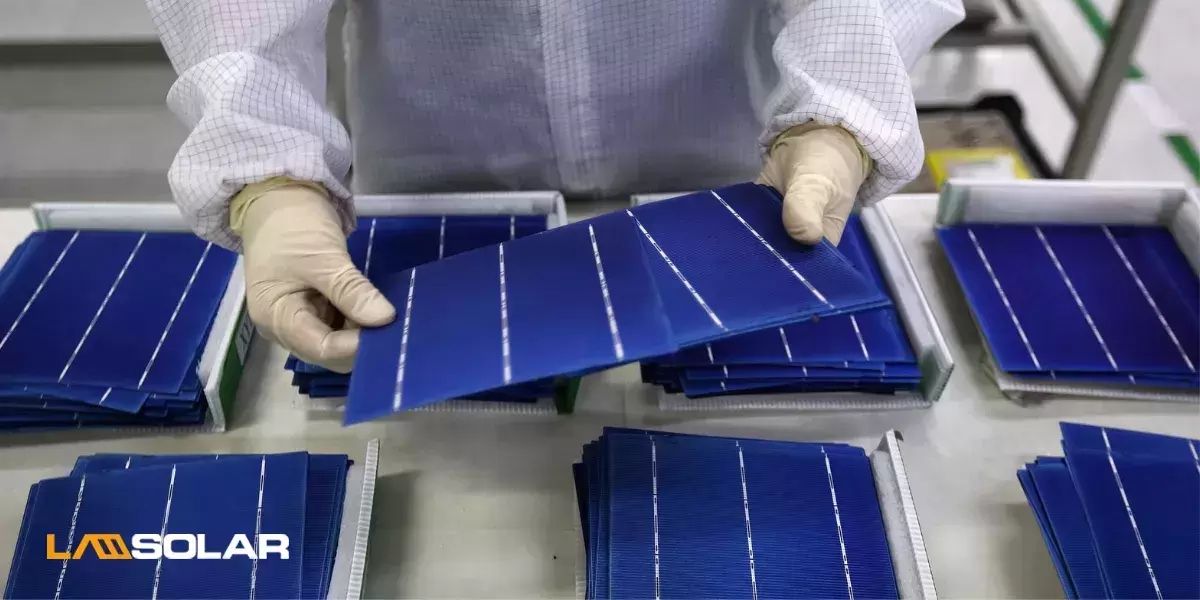

The production of photovoltaic solar panels is based on several technologies, and the purpose of each is to increase the productive efficiency of the panel. It is known that such panels are designed to absorb the sun's rays and convert them into electricity. The smallest element of the solar system is the solar cell. This article, about the thickness of human hair, is typically made of semiconductor materials, such as silicon, and is capable of producing about 1 or 2 watts.

What is PERC Technology?

In recent years, PERC technology, which was first developed in Australia in the 1980s, has stood out among solar panel manufacturing technologies. Thanks to the modernization of standard panels, PERC technology today takes the lead place in the field of solar panel production. The widespread use of this technology is due to the insignificant impact on the cost of finished products on the one hand and to the significant increase in its efficiency on the other hand.

The abbreviation PERC (Passivated Emitter and Rear Cell) translates as "Passivated Emitter and Rear Cell". There is an additional dielectric layer on the back of panels made with this technology. The sun's rays penetrating through the upper layer, hitting the lower layer, are once again reflected and directed to the silicon layer. With PERC technology, it is possible to produce both monocrystalline and polycrystalline solar panels.

Advantages of PERC Technology

Today, some manufacturers can increase the efficiency index of their products to >21.5%, which is equivalent to a power of 15 W from the supplement. Thus, thanks to PERC technology, it is possible to produce 370 W solar panels. Such panels work equally well both in sunny and gloomy weather.

Today, there are other technologies on the market whose goal is to increase the energy efficiency of solar panels. However, PERC technology is still the leader in both the international and Armenian markets. Armenian-made solar panels fully comply with international standards and stand out for their high efficiency and competitive prices.